TEL: 902-639-2311

FAX: 902-639-9010

logan@logandrillinggroup.com

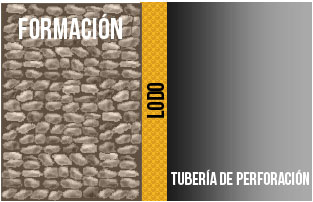

Homogeneous mixture of solid additives, liquid and / or gases in water, flow capacityand that are in suspension.

Helps drilling to be more efficient, faster, safer and more productive obtaining a more better information of each well.

Fluids perform certain functions. For this to be achieved they must have certain properties:

FUNTIONS OF DRILLING FLUIDS

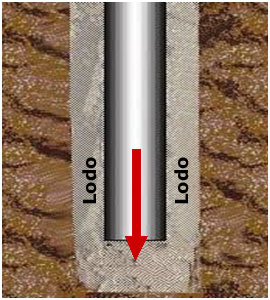

Circulated and recirculated drilled solids, smaller particles are divided. They therefore need to be controlled:

SETTLEMENT, DECANTING

Loss of movement is one factor that contributes to the high cost of sludge.

Other problems are:

The pressure generated by fluid pressure counteracts the formation of land.

The solids in the fluid form a wall that protects the formation of water invasion.

Larger materials such as cotton pit, sawdust, paper, Poly Swell and the samebentonite seal cracks, fractures where you can lose mud. They are the LCM.

HYDRATION OF CLAY

The use of lubricants reduces μk (coefficient of kinetic friction).

Drilling fluids, which can be disposed near the well are the most desirable.

recoverable or biodegradable additives are the most requested.