TEL: 902-639-2311

FAX: 902-639-9010

logan@logandrillinggroup.com

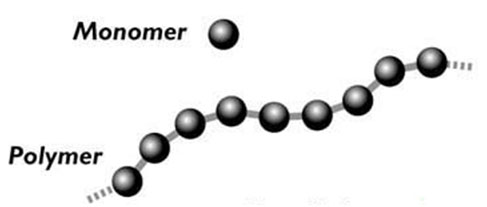

LA POLYMER IS A LARGE MOLECULE, MADE UP OF SMALL UNITS, CALLED MONOMERS SAME ANDREPEATED.

Polymer modified: Nitrocellulose, etonita, etc.

Synthetic polymers: nylon, polyethylene, polyvinyl chloride, polimetano, Bakelite, etc.

Nature Chemical: Ionic and nonionic surfactants.

Function: viscosifier and filtering driver.

Help improve the carrying capacity (transport of detritus) of the fluid.

POLYPAC (UL, R), Pac Liquid, Hibtrol, Platinum Pac, and so on.

Ensure a good seal in the pipe connections.

Provide less wear on equipment and tools.

Coat Rod B 700, Platinum Road Coat.

Thread Bond Z

Potential problems such as instability, impingement, upwelling, is worse.

Paper Drilling, Cotton Seed Hulk, Cello flake, Kwick Seal, Poly Swell, etc.

Help determine the cause of the loss, the position and the best solution.

Information on training (areas of carbonates, shales, sands, etc.)

Changes in rate of penetration.

Instability caused by: